Electronic devices are built for work, play, and everything in between. But before they reach your hands, they must prove that they can keep up with daily use. This is where reliability testing comes in. Every circuit board, chip, and module is put through trials that expose weaknesses. By simulating the wear and tear of real life, these tests ensure products can stand the heat, quite literally. Companies offering electronic manufacturing services in Singapore play a vital role here, providing the facilities and expertise needed to check every board before it goes to market.

Burn-In Testing Explained

Burn-in testing is a process that stresses a device under continuous use for hours or days. The idea is to flush out weak components early. Electronics are run at higher voltages or temperatures than normal to reveal parts that might fail later. If a board survives the burn-in, it is more likely to last for years in regular use. The process may sound harsh, but it is like a workout session that toughens up the system. By catching failures early, manufacturers save both time and costs.

Environmental Stress Screening

Another test focuses on how devices react to changes in the environment. This is called environmental stress screening. Products are exposed to temperature cycles, vibration, and even humidity. The aim is to simulate conditions a device may face in the field. For example, aerospace electronics must handle turbulence, while medical equipment must withstand constant use in controlled rooms. With these tests, engineers can spot solder cracks, loose connections, or material weaknesses. Facilities providing electronic manufacturing services in Singapore often include such testing and inspection as part of their quality assurance.

Functional Testing

Reliability also depends on whether electronics perform their intended role without error. Functional testing checks if each component does its job. From simple continuity checks to complex software-driven simulations, this stage ensures that the product delivers on its promise. A phone circuit should transmit signals, and a medical monitor must record accurate readings. Functional testing is the bridge between durability and usability.

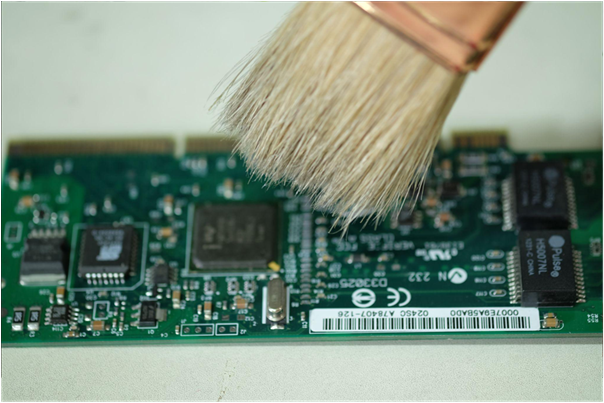

The Role of Automated Inspection

While manual checks remain valuable, automation has taken inspection to the next level. Automated optical inspection systems can scan boards quickly to spot defects like misaligned parts or soldering issues. X-ray machines can even look beneath layers of a circuit board to confirm hidden joints are intact. These systems improve speed without losing detail. They also make quality assurance more consistent, which is crucial for high-volume manufacturing.

Why These Tests Matter for Businesses

For businesses, reliability testing is more than a checklist. A product that fails in the market damages trust, reputation, and revenue. Robust testing gives clients confidence that their investment will last. This is especially vital in sectors such as healthcare and aerospace, where safety is tied directly to product reliability. By working with firms that specialise in electronic manufacturing services in Singapore, companies can secure products that meet both international standards and customer expectations.

Balancing Costs and Quality

Some may worry that extensive testing raises production costs. While it adds steps to the process, it often reduces expenses in the long run. Catching failures early prevents costly recalls or warranty claims. It also helps in refining designs for better durability. Manufacturers who prioritise reliability testing often find they save resources over time while strengthening customer loyalty.

Sustainable Approaches in Testing

Testing has traditionally consumed energy and resources, but sustainability efforts are taking shape here too. Some facilities now recycle heat during burn-in testing or use energy-efficient chambers for stress screening. Others reduce waste by reusing test fixtures or employing software simulations where possible. These practices make testing more aligned with environmental goals while keeping reliability intact.

Looking Forward

The landscape of reliability testing continues to adapt with advances in technology. As electronics become smaller and more complex, testing methods evolve to keep up. Miniaturised components call for finer inspection tools, while new materials require fresh evaluation methods. What remains constant is the need for products that can handle both expected and unexpected demands. With strong support from electronic manufacturing services in Singapore, businesses have access to the testing capabilities required to ensure their devices stand the test of time. Contact MPN Tech to ensure your electronics undergo reliable testing and reach the market ready for real-world performance.