A material so fundamental it’s practically the skeleton of our modern world, holding things together, keeping things out, and making spaces safe, yet most of us walk past it every single day without a second glance. We’re talking about welded wire mesh, that unassuming grid of steel wires fused at every intersection. It’s not glamorous, but boy, is it indispensable. From the fence around your local schoolyard to the hidden reinforcement deep within the walls of a skyscraper, welded wire mesh operates silently in the background, a silent guardian in both our personal and professional spaces. Its role in enhancing security and safety isn’t about high-tech alarms or flashing lights, it’s about providing a physical, dependable, and incredibly resilient barrier that says, “This far, and no further.” Let’s dive into the many, often overlooked, ways this humble material shapes a more secure and safer environment in our homes and businesses.

The Unshakeable Guardian Perimeter Security

When you think of security, the first image is often a boundary. A line that defines property and offers the first layer of defense. This is where welded wire mesh truly shines as the unshakeable guardian. Unlike other materials that might sag, rot, or be easily compromised, a well-constructed fence made from heavy-duty welded wire mesh presents a formidable visual and physical deterrent. The very structure of it—those precise, unwavering welds at each junction—means there are no weak points to pry apart easily. It’s a cohesive unit of strength.

For residential applications, this translates to peace of mind. A backyard enclosed with welded wire mesh fencing keeps children and pets safely within the confines of the property while keeping unwanted wildlife or intruders out. Its open weave design is crucial here, it allows for clear visibility. You can see what’s on the other side, which eliminates blind spots that solid fences create. This visibility is a safety feature in itself, fostering a sense of openness while maintaining security. There’s no place to hide against a welded wire mesh fence, making it a less attractive option for anyone with ill intent. The psychological barrier is just as strong as the physical one.

In commercial and industrial settings, the stakes are often higher, and the welded wire mesh used is accordingly more robust. Think of storage yards for construction equipment, compounds for utility substations, or perimeter fencing for warehouses. Here, welded wire mesh is often fabricated into panels that are rigid, difficult to climb, and resistant to cutting tools. It protects high-value assets not just from theft but from vandalism and accidental trespass that could lead to serious liability issues. The durability of galvanized or PVC-coated welded wire mesh means this security stands up to harsh weather year after year with minimal maintenance, providing a long-term, cost-effective security solution that never clocks out.

The Invisible Protector Structural and Internal Safety

Now, let’s step inside the buildings themselves. While the perimeter fence is the visible shield, welded wire mesh plays another, completely invisible, role as the protector within. This is where its function shifts from keeping threats out to holding everything together, literally. In construction, welded wire mesh is a superstar in concrete reinforcement. Plaster or stucco applied over a layer of welded wire mesh is far less likely to crack and crumble away from the underlying structure. This mesh acts as a tensile skin, holding the material in place and distributing stress across a wider area.

This is a massive safety benefit. On commercial buildings, it prevents dangerous pieces of façade from loosening and falling. In residential basements or foundations, welded wire mesh-reinforced concrete is stronger and more resistant to shifting soils and water pressure. But it goes beyond walls. Think about the floors under your feet. In many concrete slab applications, a sheet of welded wire mesh is laid before the pour. This controls cracking and ensures the slab behaves as a single, unified plate. This is critical for safety in everything from your garage floor to the vast expanse of a factory warehouse. A cracked, uneven floor is a tripping hazard and a sign of structural weakness, welded wire mesh helps prevent that at the source.

Another fascinating internal safety application is in machine guarding and partitions within facilities. In workshops, factories, or even commercial kitchens, it’s often necessary to separate processes or contain hazards while maintaining airflow and visibility. Welded wire mesh is perfect for this. It can be used to create secure cages around dangerous machinery, preventing accidental contact with moving parts. It can serve as a protective screen in areas where debris might fly, like grinding stations. In these roles, its open design allows light and air to circulate and for supervisors to monitor activity, all while creating a crucial physical barrier between people and potential danger. It’s safety through separation, without isolation.

The Everyday Safety Net From Gardens to Guardrails

The versatility of welded wire mesh means its safety benefits trickle down into the most everyday scenarios. It’s the unsung hero of mundane yet critical applications. Consider garden fencing made from a lighter gauge welded wire mesh. It’s not just for keeping rabbits out of the lettuce. It can be used to create safe, contained compost bins, support climbing plants safely without risk of collapse, or even as a sturdy base for a homemade greenhouse. In each case, it’s providing structure and a managed boundary that prevents accidents and organizes space safely.

Then there are applications like balcony infill or deck railings. While glass and metal bars are common, welded wire mesh panels offer a superb alternative. They provide a fail-safe barrier that is particularly good for homes with small children or pets, as the openings are too small for a child to squeeze through, yet the view remains largely unobstructed. Similarly, in commercial settings, welded wire mesh is used for mezzanine guardrails, stairwell barriers, and protective screening on loading docks. Its strength ensures it can withstand impact, and its construction means it won’t shatter or develop hidden fractures like glass might.

We also can’t ignore its role in animal and agricultural safety. Welded wire mesh enclosures keep livestock securely contained, protecting them from predators and preventing them from wandering onto dangerous roads. Aviaries and zoo habitats rely on specific types of welded wire mesh to create safe, spacious environments for animals. Even in residential settings, a sturdy welded wire mesh kennel provides a safe outdoor space for a dog. In every case, the material is defining a safe zone, protecting what’s inside and sometimes protecting the outside from what’s within.

Choosing the Right Mesh for the Job

Of course, not all welded wire mesh is created equal, and its effectiveness in security and safety hinges on choosing the right type. It’s like choosing a tool, you wouldn’t use a sledgehammer to hang a picture. The variables are key: the wire gauge (thickness), the mesh opening size, and the coating. For a high-security perimeter, you’d look for a heavy gauge (like 6mm or thicker) with small openings, likely hot-dip galvanized for maximum corrosion resistance. This combination resists cutting, climbing, and weathering.

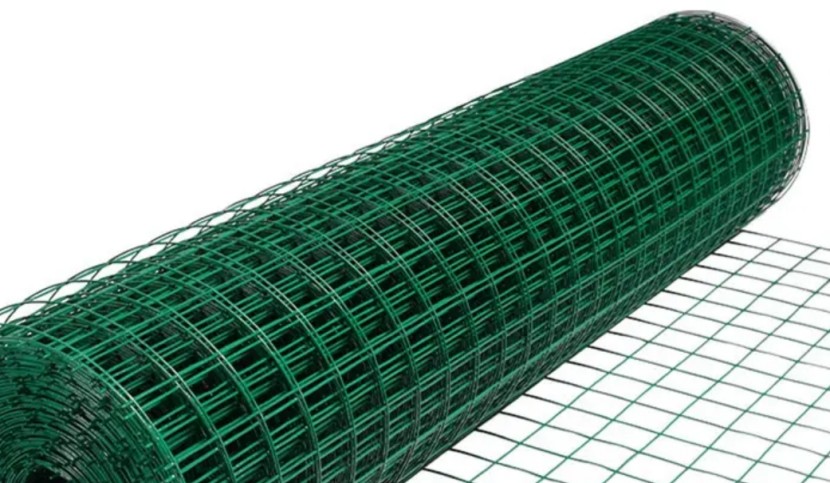

For internal concrete reinforcement, a lighter, galvanized welded wire mesh sheet in a standard grid pattern is typical. The welds must be consistent to ensure uniform strength transfer. For animal enclosures, the coating is critical—PVC-coated welded wire mesh is excellent as it resists the acidic nature of animal waste and won’t rust, creating a longer-lasting and safer enclosure. Understanding these nuances is what allows builders, safety officers, and homeowners to harness the full protective potential of this adaptable material. It’s a system, and specifying the correct welded wire mesh is the first step in building a safer environment.

So, the next time you pass a construction site, glance at a fence, or even lean on a concrete wall, remember the silent, grid-like guardian at work. Welded wire mesh is far more than just metal in a grid, it’s a deliberate engineering solution for managing space, force, and risk. Its value lies in its paradoxical nature: it is a barrier that allows for transparency, a flexible sheet that provides immense rigidity, and a simple product that solves complex safety and security challenges. In a world where we often overcomplicate things, welded wire mesh stands as a testament to the power of straightforward, robust, and intelligent design in creating safer homes and more secure businesses. It is, quite literally, the fabric that holds our safe spaces together.