In today’s competitive manufacturing environment, ensuring a smooth and efficient production line is essential. Any interruption or downtime can result in significant losses, reduced productivity, and delays in meeting customer demands. One technology that plays a crucial role in improving production reliability is industrial compression. By optimizing processes and enhancing equipment performance, industrial compression solutions help businesses maintain consistent operations and reduce unexpected failures.

Understanding Industrial Compression

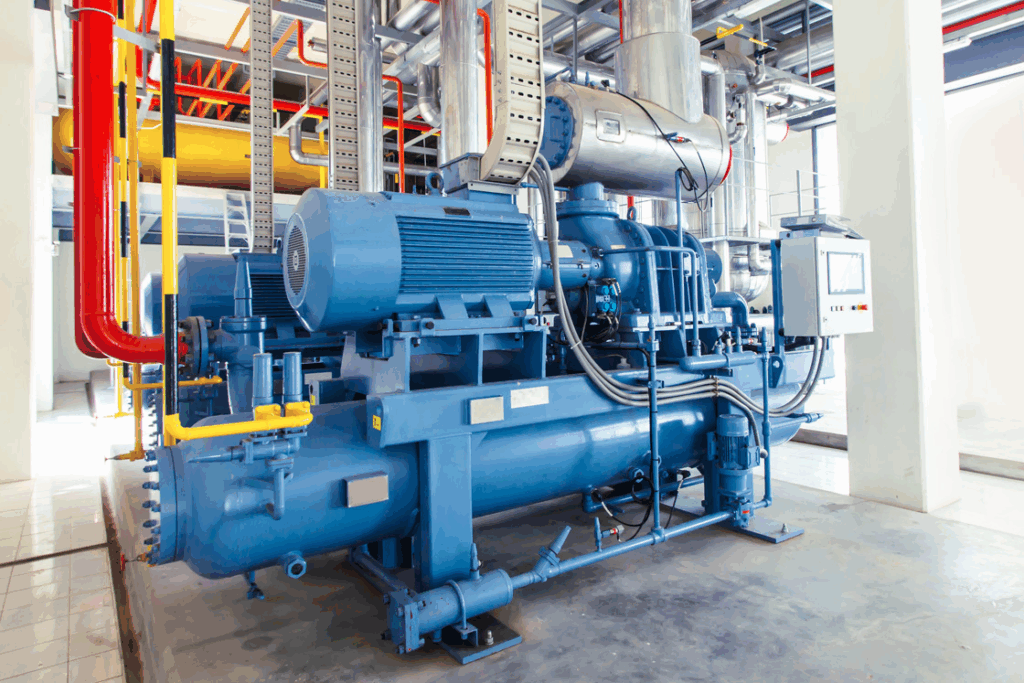

Industrial compression refers to the use of compressors and related systems to increase the pressure of gases or air for various industrial processes. These systems are essential in factories, processing plants, and assembly lines where machinery relies on compressed air or gas for operation. From powering pneumatic tools to supporting automated equipment, industrial compression ensures that machines work efficiently and without interruption. Implementing the right compression system can significantly impact the overall productivity and reliability of your production line.

Benefits of Industrial Compression for Production Reliability

Using industrial compression in a production setting brings several advantages. First, it provides a consistent and stable supply of compressed air or gas, which is critical for operating machinery that depends on precise pressure levels. This stability minimizes the risk of equipment malfunction or breakdown. Additionally, modern industrial compression systems are designed to be energy-efficient, reducing operational costs while maintaining high performance. By investing in reliable compression equipment, manufacturers can also extend the lifespan of their machines, avoiding frequent repairs and maintenance issues.

Reducing Downtime with Industrial Compression

Downtime is one of the biggest challenges in any production facility. Even a short interruption can lead to missed deadlines and lost revenue. Industrial compression systems play a vital role in minimizing downtime by ensuring that essential machinery has a constant supply of energy. Advanced systems come with monitoring and control features that detect potential issues before they become serious problems. This proactive approach allows maintenance teams to address minor faults early, preventing major disruptions and keeping the production line running smoothly.

Enhancing Efficiency and Productivity

Industrial compression does more than just keep machines running; it also helps improve overall efficiency. Compressed air and gas systems can be customized to meet the specific needs of a production line, allowing for more precise control over manufacturing processes. This precision reduces waste, increases output quality, and enables smoother coordination between different stages of production. When your production line operates efficiently, you can achieve higher throughput and better product consistency, which is vital for meeting customer expectations.

Choosing the Right Industrial Compression System

Selecting the right industrial compression system is crucial to achieving maximum reliability. Factors such as the size of the production line, type of machinery, and pressure requirements should guide the decision-making process. Working with experts in industrial compression can help identify the best solutions for your specific needs, ensuring that your investment delivers long-term benefits. A well-designed compression system not only supports existing equipment but can also accommodate future expansion or upgrades.

Maintaining Your Industrial Compression System

Even the most advanced industrial compression systems require regular maintenance to remain effective. Routine inspections, filter changes, and monitoring of system performance are essential to prevent unexpected failures. By implementing a proper maintenance schedule, manufacturers can reduce the risk of downtime and ensure that their production line continues to operate reliably. Maintenance also contributes to energy efficiency, helping businesses save on operating costs while sustaining optimal performance.

Conclusion

Industrial compression is a key factor in making production lines more reliable. By providing a stable and efficient source of compressed air or gas, these systems help minimize downtime, enhance productivity, and extend the life of machinery. Choosing the right compression solution and maintaining it properly ensures that your manufacturing operations run smoothly, consistently meeting production goals. Investing in industrial compression is not just about powering equipment—it is about creating a more dependable and efficient production process that supports long-term business success.