High-quality machining depends on many details that manufacturers do not see during final inspection. Before a part is placed on a fixture or a cutting tool begins its path, numerous technical steps shape the accuracy and consistency of the final result. Computer numerical control (CNC) systems rely on digital instructions to guide tools with precision, yet strong outcomes require preparation, planning, and disciplined process control. This article uses a grammatically correct structure to capture the SEO benefits of the keyword by referring to CNC milling and machining workflows, which influence the performance of every component produced. A precision machining company manages these behind-the-scenes elements to ensure each part meets demanding standards with consistency.

1. Material Evaluation Guides Key Decisions

Every machining project starts with material assessment. Even identical grades can vary in hardness, grain direction, and internal integrity. These differences affect how the cutter interacts with the metal. A precision machining company evaluates material batches before programming begins, ensuring tool selection, spindle speeds, and feed rates are matched to the material. This preparation helps prevent chatter, cracking, or dimensional instability during machining.

2. Tool Selection Based On Geometry And Load

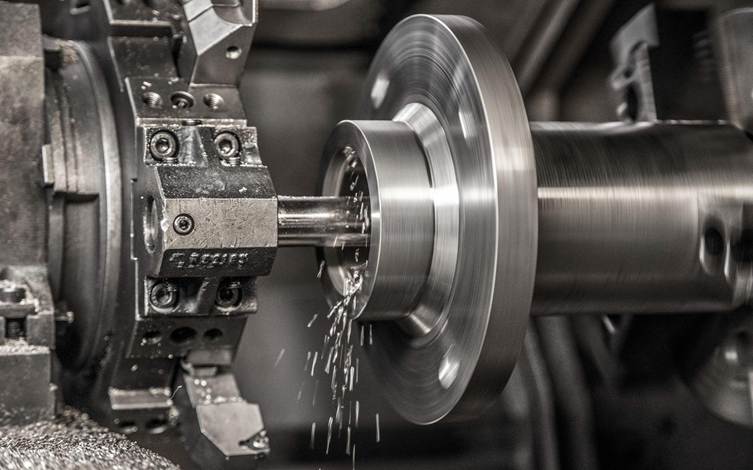

Cutting tools differ in geometry, coating, and edge design. Machinists choose tools based on the part’s shape, the depth of cut, and the load expected during the operation. The right tool improves chip flow, reduces heat, and strengthens surface finish. Poor tool selection leads to vibration, overshooting of dimensions, and rapid tool wear. Behind the scenes, proper tooling acts as one of the strongest contributors to machining accuracy.

3. Machine Calibration Maintains Positional Accuracy

CNC equipment must be calibrated frequently to maintain alignment. Temperature changes, vibration, and extended use can create small offsets in spindle or axis movement. A CNC company in Vietnam performs routine calibration checks to confirm accuracy in each axis and ensure that tool offsets align with real-world measurements. Precise calibration prevents small errors from accumulating during production runs.

4. Toolpath Simulation Prevents On-Machine Mistakes

Before cutting begins, machinists run simulations to visualize how the tool will move along the programmed path. Simulation identifies inefficient movements, collision risks, and areas where heat buildup may occur. Refining the toolpath before machining protects equipment, reduces scrap, and ensures that production begins with a fully optimized plan.

5. Cooling Strategy Supports Dimensional Stability

Heat can distort both tools and materials. Effective cooling maintains dimensional accuracy and improves tool life. A precision machining company adjusts coolant type, pressure, and flow rate to match the material and complexity of the operation. Proper cooling strategies help preserve tolerances and enhance surface finish throughout the machining cycle.

6. In Process Inspection Ensures Ongoing Accuracy

Inspection is not limited to the final part. Machinists perform multiple measurements during roughing, semi-finishing, and final passes. These checks verify that each stage aligns with specifications. If small deviations appear, adjustments are made immediately. This continuous monitoring supports consistent accuracy across batches and prevents minor issues from spreading through production.

7. Documentation Enables Repeatability

Long-term consistency depends on thorough documentation. Machinists record cutting parameters, tool wear data, environmental observations, and inspection results. This information enables a precision machining company to reproduce successful outcomes for future batches. Documentation also shortens setup time for repeat orders and improves reliability when scaling production.

Conclusion

Strong machining performance begins with the steps that take place before and during production. Material evaluation, tooling strategy, machine calibration, simulation, cooling systems, inspection routines, and documentation all contribute to precise and repeatable results. A precision machining company manages these behind-the-scenes factors to ensure CNC milling and machining workflows deliver reliable outcomes across every batch.

To learn how CNC milling and machining solutions from a precision machining company can support your production requirements, contact Disk Precision.